Experiencing thermodynamics instead of just calculating it – how digital interactive laboratory technology is changing university teaching

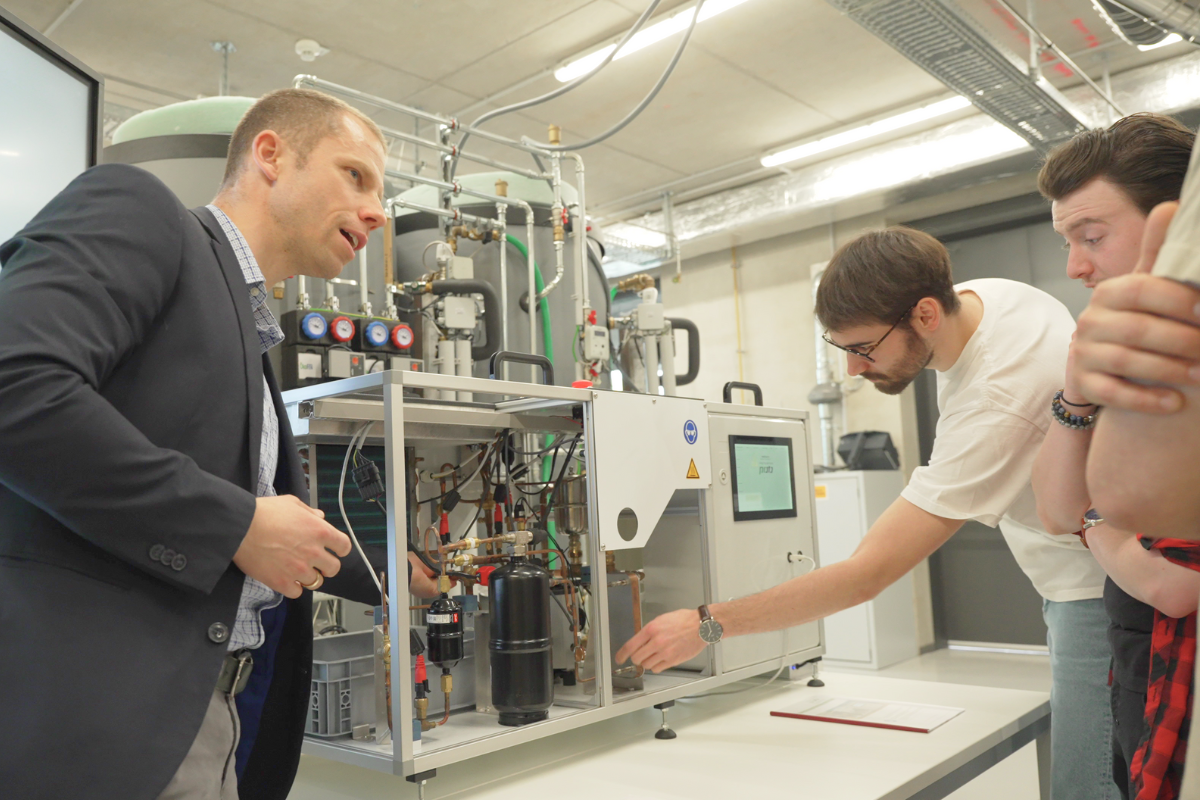

Energy efficiency, climate protection, and sustainability are among the key challenges in engineering education today. In order to introduce students to complex thermodynamic processes not only theoretically but also practically, universities are increasingly turning to innovative teaching and laboratory technologies. A current example is the heatXpump, which shows how heat pump and refrigeration technology can be integrated into teaching in a practical way. In traditional thermodynamics lecturers, the physical process often remains abstract. However, the use of modern measurement technology makes it visible and tangible: students can follow real cycles live, analyze measured values, and compare their theoretical models directly with practice. This strengthens both their understanding of fundamental principles and their motivation to study. The laboratory unit used at the University of Applied Sciences Wiener Neustadt, for example, enables heat pump and refrigeration cycles to be observed in detail. Process data is recorded in real time and visualized graphically using sensors (temperature, pressure, flow). Thanks to process reversal, the system can be operated in both heating and cooling modes. This allows COP, EER, superheating, and Carnot’s cycle to be researched in a practical manner.

Comprehensive measurements: Thanks to numerous temperature, pressure, and flow sensors as well as sight glasses.

The system was first used in 2025 in the thermodynamics laboratory at the University of Applied Sciences Wiener Neustadt. Students independently carry out measurement series, observe effects such as evaporator icing or defrosting processes, and compare their results with theoretical models.

Teachers report greater student engagement, a deeper understanding, and greater independence in problem analysis. The teaching staff also enjoys this interactive teaching method more due to the increased participation.

The integration of these technologies into technical teaching not only supports practical training, but also helps to secure skilled workers in the energy sector. Looking ahead to the energy transition, building technology, and sustainability, practical skills are crucial for aspiring engineers. Interactive digital teaching systems provide low-threshold access to complex physical processes and bridge the gap between theory and application.

Ethernet and Wi-Fi make it easy to integrate systems into existing teaching structures and also enable connection to building management systems. This not only makes teaching more practical, but also future-oriented and digitally compatible.

Innovative teaching systems for heat pump and refrigeration technology open up new didactic possibilities in thermodynamics, building technology, and energy technology. They support universities in actively involving students in the learning process and better preparing them for the challenges of the energy transition.

Interactive digital handling enables the immediate implementation of the thesis-antithesis-synthesis relationship. Students can thus test and deepen their knowledge. The heatXpump was developed into a series product by Protovation GmbH and is commercially available. It offers a wide range of additional teaching content in the fields of hydraulics, refrigeration technology, electrical engineering, and heat pump technology. This allows teaching to be carried out at a very high technical level, e.g., through the option of setting the expansion valve for overheating or the option of observing a temperature curve through the wall with three measuring points. However, it can also be used at a more moderate technical level, e.g., by influencing sound depending on the shape of the fan blades. This allows the heatXpump to be integrated into various fields of study.

Does this sound interesting to you? Contact us at office@protovation.at for more information.

As an engineering firm and company, Protovation GmbH develops innovative technical systems for energy technology, circular economy, and applied teaching—from the initial idea to practical implementation. In addition to customer-specific industrial projects, we also develop teaching and demonstration systems that are used to teach technical processes in a practical manner at universities – e.g. our heat pump #heatXpump for energy technology or our Power-to-X device #coXrr for circular economy.

Protovation GmbH

Halle 4 / Stand 4H125

Wiener Straße 54

3300 Amstetten

AUSTRIA

Tel: +43 664 2393207

Dr.techn. Stefan Stadlbauer