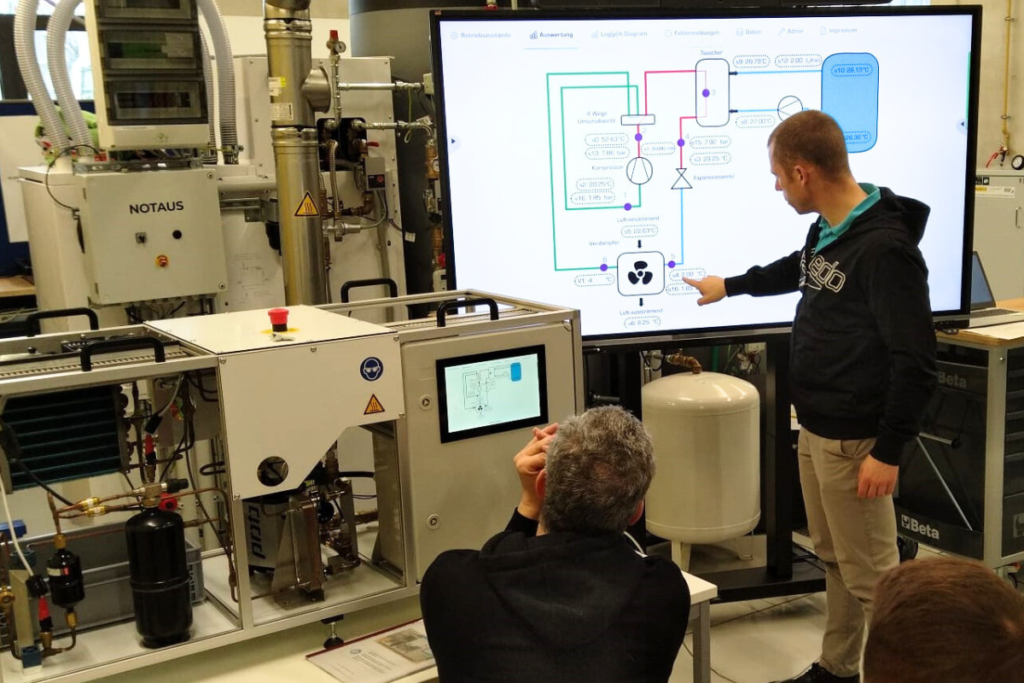

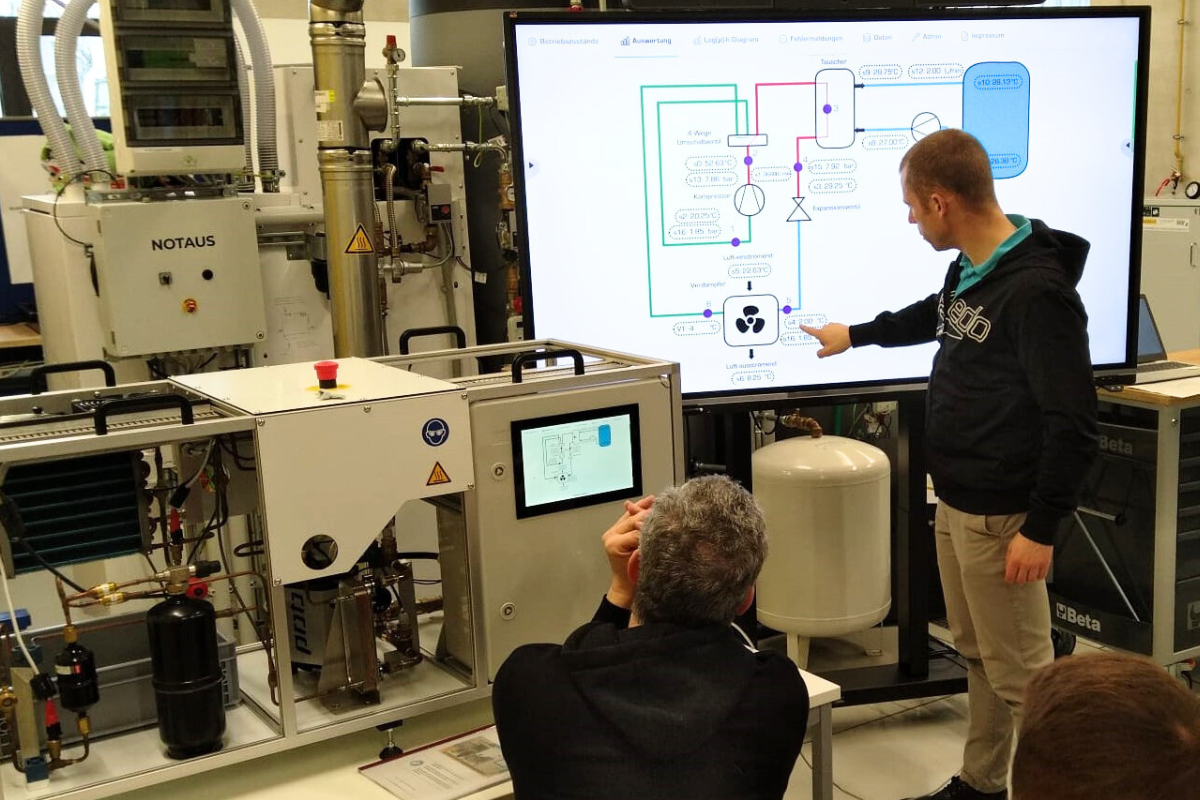

Bringing theory to life: With the heatXpump, students can simulate real heat pump and refrigeration cycle processes and analyze measurement data in real time. An interactive demonstrator for professors at technical universities.

The heatXpump, developed by Protovation GmbH in Lower Austria, is a teaching tool for technicians at various levels of education (college, university, industrial research) and is an excellent instrument for enabling interactive engagement with the topics of measurement and testing in thermodynamics. Various topics such as heat pump technology, refrigeration technology, and energy technology can be learned and experienced safely and up close. The heatXpump has a process reversal, which means that the mobile system can be operated both as a heat pump and as a refrigeration machine with low voltage (48Vdc). Numerous temperature sensors, pressure sensors, flow sensors, and sight glasses at various points in the refrigeration cycle record and log comprehensive measurement values, which are then displayed interactively and live. This allows numerous process parameters to be checked. Among other things, the COP in heating mode, the EER in cooling mode, the superheating of the suction-side refrigerant, the spread of the air and hydraulics, the Carnot cycle, and much more can be checked. However, even less accessible phenomena can be measured and checked. For example, the icing of the evaporator can be easily observed and checked, as can the subsequent defrosting due to the process reversal.

Various defrosting logics can thus be checked for efficiency. Attention is also paid to the topic of sound, which allows the effect of fan geometries on measured noise levels to be checked.

All in all, the heatXpump is an attractive teaching tool that makes it easier to convey the complex subject of thermodynamics in an exciting way at technical universities. Thanks to the newly integrated Ethernet interface, the heatXpump can now also be integrated into laboratory setups with building management systems, keeping it absolutely up to date. This means that performance data for the heat pump or refrigeration machine can now also be measured and checked as a function of the control system via the building management system based on, for example, weather data or changes in electricity prices. The integrated buffer storage tank of the heatXpump can also be switched as a hydraulic switch, allowing the heat or cold to be specifically decoupled via the interface.

The heatXpump is already available and ready to produce well-trained technicians in the field of sustainable energy. Various teaching content for different technical education levels and the needs of individual technical areas are waiting to be discovered and will brighten up your lecture with interactive discussion.

Does this sound interesting to you? Contact us at office@protovation.at for more information.

As an engineering firm and company, Protovation GmbH develops innovative technical systems for energy technology, circular economy, and applied teaching—from the initial idea to practical implementation. In addition to customer-specific industrial projects, we also develop teaching and demonstration systems that are used to teach technical processes in a practical manner at universities – e.g., our heat pump #heatXpump for energy technology or our Power-to-X device #coXrr for circular economy.

Protovation GmbH

Halle 4 / Stand 4H125

Wiener Straße 54

3300 Amstetten

AUSTRIA

Tel: +43 664 2393207

Dr.techn. Stefan Stadlbauer